Introduction

Corrugated paper is a board made of corrugated paper made of corrugated paper and corrugated paper formed by corrugated sticks. It is generally divided into two types: single corrugated cardboard and double corrugated cardboard. According to the size of corrugated: A, B, C , E, F five types. The invention and application of corrugated paper has more than one hundred years of history. It has the advantages of low cost, light weight, easy processing, high strength, excellent printing adaptability, convenient storage and handling, etc. More than 80% of corrugated paper can be recycled and recycled. Corrugated paper It can be used as a packaging for food or digital products. It is relatively environmentally friendly and widely used.

Use

Type A corrugated and type B corrugated boxes are generally used for transporting outer packaging boxes, and beer boxes are generally made of B corrugated. E corrugated is used as a single-piece box with certain aesthetic requirements and appropriate weight contents. F corrugated and G corrugated whip are called micro-corrugated, which is a very thin corrugated, used as a hamburger, creamy pastry and other foods. Disposable packaging containers, or used as micro-electric products such as digital cameras, portable stereos, and packaging for refrigerated goods.

Cardboard

Corrugated paperboard began in the late 18th century. At the beginning of the 19th century, due to its light weight and low price, it was widely used, easy to manufacture, and can be recycled or even reused, which led to a significant increase in its application. By the beginning of the 20th century, it has been widely popularized, promoted and applied for packaging and packaging of various commodities. Since packaging containers made of corrugated cardboard have unique properties and advantages for beautifying and protecting the interior goods, they have achieved great success in competition with various packaging materials. It has become one of the main materials for making packaging containers that have been used up to now and are rapidly developing.

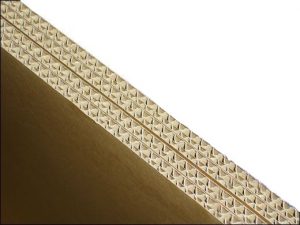

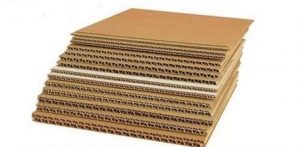

Corrugated cardboard is made by bonding paper, backing paper, core paper and corrugated paper processed into corrugated corrugated. According to the requirements of commodity packaging, corrugated cardboard can be processed into single-faced corrugated cardboard, three-layer corrugated cardboard, five-layer, seven-layer, eleven-layer corrugated paperboard. Single-faced corrugated cardboard is generally used as a lining protective layer for commercial packaging or to make lightweight krafts and bolsters to protect the goods from vibration or impact during storage. Three-layer and five-layer corrugated cardboard are used in corrugated boxes. common. Many products are packaged in simple and beautiful packaging through three or five layers of corrugated cardboard. Colorful patterns and images are printed on the surface of corrugated boxes or corrugated boxes, which not only protects the inner goods, but also promotes and beautifies the inner commodity. Many corrugated boxes or corrugated boxes made of three- or five-layer corrugated cardboard have been directly put on the sales counter and become sales packaging. Seven-layer or eleven-layer corrugated cardboard is mainly used for making boxes for electromechanical, flue-cured tobacco, furniture, motorcycles, and large household appliances. In a specific product, the corrugated cardboard combination can be used to make the inner and outer casings, which is convenient for production and convenient for the storage, storage and transportation of the goods. With the needs of environmental protection and the requirements of relevant national policies, the packaging of such corrugated cardboard products has gradually replaced the trend of wooden packaging.

Carton

Corrugated boxes are made from corrugated cardboard and are the most widely used paper container packaging for transport packaging. Corrugated boxes are widely used because of their unique advantages: 1 good cushioning performance. 2 Light and firm. 3 small size. 4 sufficient raw materials and low cost. 5 facilitate automated production. 6 packaging operations cost is low. 7 can pack a variety of items. 8 metal consumption is small. 9 printing performance is good. 10 can be recycled and reused.

Composite board

Corrugated composite board is a new type of material that is emerging after the introduction of honeycomb paperboard by the United States and Europe. It is a new material that saves resources, protects the ecological environment and is relatively low in cost. It is a new generation of high-quality intellectual property rights in China from the entire automatic production line equipment to finished products. Technological Achievements. The finished product is light in weight, high in strength, non-deformation, good in rigidity, strong in cushioning performance, good in sound insulation and heat insulation effect, and can be flame-retardant, moisture-proof, waterproof, and has lower requirements on raw materials than honeycomb paperboard, and can be recycled. Paper and old corrugated boxes are used to produce raw materials, so the raw materials are widely available. After the finished product is used, it can be recycled and rebuilt, which meets the environmental protection requirements of resource recycling and has a wide application prospect. Corrugated paper composite panels can be made into various precision instruments, electromechanical equipment, household appliances, ceramic packaging boxes, liners, etc., can also be made into various specifications of trays, cushioning liners, aviation turnover boxes; use of corrugated paper in building materials The composite board can be made into a lightweight partition wall, a sound insulation board, a heat insulation board, furniture, and a disposable beach table, and can also be used to make a disposable disposable cremation sanitary aseptic paper basket.